| Sign In | Join Free | My portofva.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My portofva.com |

|

Brand Name : DIXUN

Model Number : DX-ZDW-115

Certification : CE

Place of Origin : China

MOQ : One set

Supply Ability : 6 sets per month

Delivery Time : 30 working days

Packaging Details : 1.main machine and accessory equipment will be packed with sketch film paper; 2.control cabinet and spare parts will be packed with the wooden box; 3.finally all the machines will be fixed with hornwoods and steel oil wire rope,ensure them stable and not

Product name : Brick Force Mesh Welding Machine

Wire diameter : 1.6-3.0mm

Mesh size : 75mm,115mm,230mm

Length of coil mesh : 20m one roll

Main motor : 4.0kw

Longitudinal wire type : Coil wire feeding

Cross wire type : Pre-cut

Control system : By PLC

Machine weight : 3500kg

Machine dimension : 4500*1000*1100mm

Power consumption : 3-5kw/h

Floor space : 15*3m

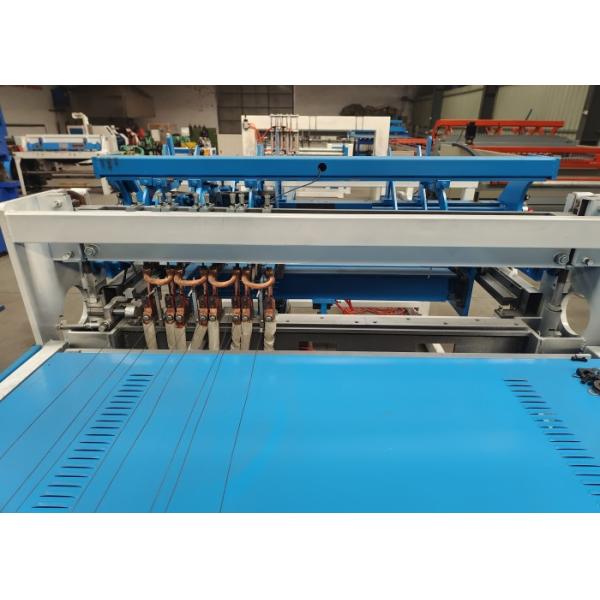

Coil Mesh Length 20m Mesh Size 115mm Brick Force Mesh Welding Machine

Introduction of Brick Force Mesh Welding Machine:

The brick force mesh welding machine can make the brick force mesh for construction. The finished brick force mesh is in rolls and the machine can output four brick force mesh rolls at the same time. It is easy to operate and maintain. The brick force mesh is used in the brickwork reinforcement. It can be black brickforce or galvanized brickforce.

Features of Brick Force Mesh Welding Machine:

1. This machine adopts programmable logic controller (PLC) for control, and adjustment is simple, stable and reliable.

2. Using touch screen operation, simple, convenient and natural human-computer interaction.

3. Due to the precise processing of parts and strict quality control, after installation and commissioning, under normal working conditions, it can maintain trouble-free operation for a long time.

4. Particularly suitable for steel bar processing, such as housing construction, steel welded mesh, etc.

5. The machine adopts servo motor with high precision and good stability.

6. The machine adopts synchronous control technique.

7. The welding time and separate welding are controlled by PLC for system digital input panel or touch screen buttons.It can be more intelligent operations and rationalizing.

8. The advantages of the device are stable performance ,strong welding spot and accurate weldingaperture.

9. The machine adopts synchronous control technology of power electric,auto-sharding,automatic rolling,high yield,stable performance,strong welding spot,without welded tracks.

3. The components of the brick force mesh welding machine:

Main welding part 1unit

Mesh coiling part 1unit

Auxiliaries needed:

Wire straightening and cut machines 2 sets

Line wire straightening rollers 1set

Line wire payoffs 6sets

Electric cutting tool 1piece

Technical Parameters of Brick Force Mesh Welding Machine:

| Model | DX-ZDW-115 |

| Welding wire diameter | 1.6-3.0mm |

| Longitudinal wire size | 75mm,115mm,230mm |

| Welding press | Resistance welding |

| Welding speed | 60 times per min |

| Cross wire size | 50-300mm |

| Welding transformer | 120KVA |

| Number of welding electrode | 8 pcs |

| Material of welding electrode | CuCrZr |

| Supply transformer capacity | 80 kva |

| Voltage | 220V 380V 415V 440V 50Hz or 60Hz |

| Welding type | SCR Controlled |

| Labor cost | One person |

| Mesh width | Max.300mm |

| Finished product | 4 rolls mesh |

Applications of Brick Force Mesh Welding Machine:

It is usually applied to wall reinforcement,has the characteristics of seismic resistance.

Photos of Brick Force Mesh Welding Machine:

|

|

Coil Length 20m Size 115mm Brick Force Wire Mesh Welding Machine 4.0kw Power Saving Images |